Search

4.5 Ton 2 Post Overhead Clearfloor

• Single point lock release

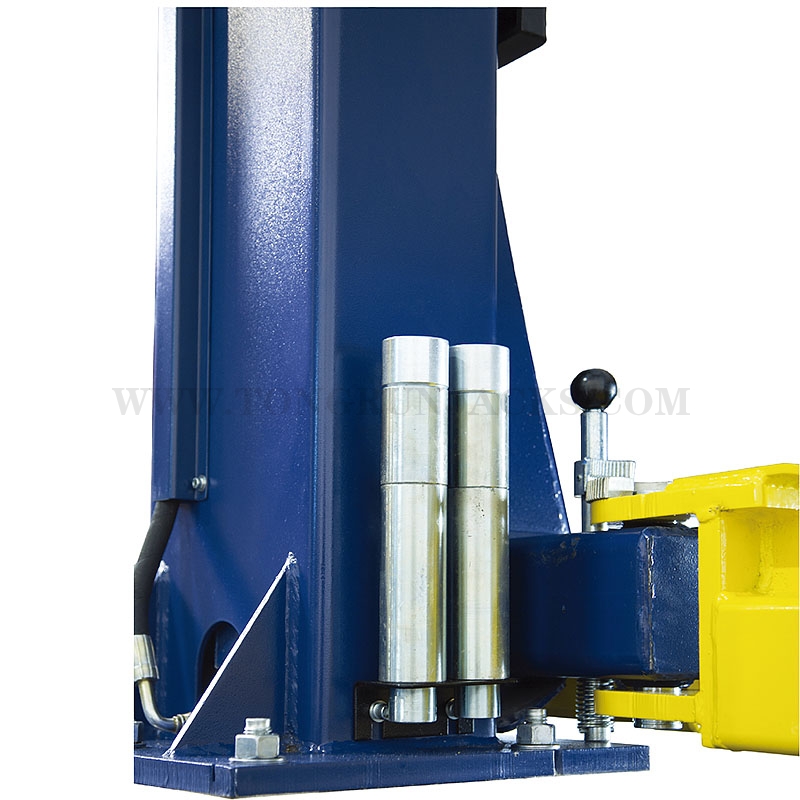

• Dual direct drive hydraulic cylinders

• Oversized 57 degree tall lifting carriages

• Automatic arm restraints

• Truck adapter kit

• Triple telescoping arm design

• Steel aircraft quality equalizing cables

• Matted powder coat finish

• Max rise height with adapters 78-in. (1981mm)

• Three optional variable drive through clearances

Product description

Product Information

The ALI CERTIFIED 10,000-lb. Overhead Commercial Lift is the newest and best solution that provides ample door opening clearance for entry to vehicles. Each lift is designed using a single piece column, a variable overhead cross-member, and extra tall carriages that all combine to create a very strong and reliable lift design.

|

Model |

T10000-20H-33 |

Capacity |

4.5 Ton |

|

Max. Rise from ground |

1848 mm |

Lifting Range |

1745 mm |

|

Lowest Clearance from the ground |

103 mm |

Narrow Drive-Thru Clearance |

2239 mm |

|

Medium Drive-Thru Clearance |

2389 mm |

Wide Drive-Thru Clearance |

2359 mm |

|

Standard Overall Height |

3650 mm |

Tall Overall Optional Height |

4235 mm |

|

Max. Load Per Arm |

1136 kgs |

Lift Structure Weight |

860 kgs |

|

Shipping Dimensions |

3605x570x955 mm |

Power Unit Weight |

27.2 kgs |

|

Shipping Dimensions |

900x280x320 mm |

24" Height Extender Weight |

76.2 kgs |

|

Shipping Dimensions |

770x440x430 mm |

QTY/40'CY |

22 PCS |

Features

• 10,000-lb. Lift capacity

• Single point lock release

• Dual direct drive hydraulic cylinders

• Oversized 57 degree tall lifting carriages

• Automatic arm restraints

• Truck adapter kit

• Triple telescoping arm design

• Steel aircraft quality equalizing cables

• Matted powder coat finish

• Max rise height with adapters 78-in. (1981mm)

• Three optional variable drive through clearances

Common Problems And Solutions

Sequence of Lockout Procedure

1) Notify all affected employees that a lockout is being performed for servicing or maintenance and that the lift must be shut down and locked out to perform the servicing or maintenance

2) Unload the subject lift (remove vehicle). Shut it down and assure the disconnect switch is "OFF" if one is provided on the lift.

3) The authorized lockout person operates the main energy isolation device removing power to the lift being taken out of service. Stored or residual energy (such as capacitors, springs, elevated machine members, hydraulic systems, air, or etc.) must be dissipated or restrained by methods such as grounding, repositioning, blocking, bleeding down, etc.

If this is a lockable device, the authorized lockout person places the assigned padlock on the device to prevent its unintentional reactivation. An appropriate tag is applied stating the person's name, at least 3" x 6" in size, an easily noticeably color, and states not to operate device or remove tag. If this device is a non-lockable circuit breaker or fuse, replace circuit with a "dummy" device and tag it appropriately as mentioned above.

4) Ensure that the equipment is disconnected from the energy sources' by first checking that no personnel are exposed, then verify the isolation of the equipment by operating the push button or other normal operating controls' or by testing to make certain the equipment will not operate. . Be sure to return any switches to the "OFF" position.

5) The equipment is now locked out and ready for the required maintenance or service.

Restoring Equipment to Service

1) Check the lift and the immediate area around the lift to ensure that nonessential items have been removed (clear all tools, vehicles and personnel) and that the completion of all lift components are operationally intact.

2) The authorized person can now remove the lock (or dummy circuit breaker or fuse) and tag. Activate the energy isolating device so that the lift may again be placed into operation.

Scan the QR code to read on your phone

Previous

4.5 Ton Four Post Lift

Next

None

- TOP