Search

150Ton Hydraulic Shop Press

• Lead-free paint finish is applied after a thorough chemical wash to ensure a long-lasting finish and to help prevent rust

• Paint is oil, grease and dirt-resistant for easy cleanup

• High quality large diameter hydraulic steel cylinder unit results in lower oil pressure needed to raise the load, helping to reduce wear and extend service life

• Piston-ram is treated and polished to resist skiving

• Piston-ram utilizes a Y-Style polyurethane sealing ring with backup ring, preventing load from falling slowly or bypassing oil drift

• Hydraulics are powered with a high quality oil, which offers better corrosion resistance and high/low temperature flexibility, allowing the unit to operate at temperatures between 40 degrees F and 105 degrees F • Extra-long handle included for easy pumping force

Product description

Product Informatio

This equipment is designed for automotive, truck, implement, fleet, and industrial repair shops where pressing, bending, straightening and forming tasks are required. Typical applications include installation and removal of alternator and power steering pump bearings, axle bearings, transmission bearings, seals, U-joints and many other jobs.

|

Model |

TRD515001 |

Capacity |

150 Ton |

|

Stroke |

350 mm |

Work Range |

0~950 mm |

|

N.W. |

1300 kgs |

G.W. |

1350 kgs |

|

Package Size |

1470x2270x650 mm |

QTY/20'CY |

10 PCS |

Features

• Heavy-duty H-frame constructed of high-grade steel and built to exacting standards for quality and durability

• Lead-free paint finish is applied after a thorough chemical wash to ensure a long-lasting finish and to help prevent rust

• Paint is oil, grease and dirt-resistant for easy cleanup

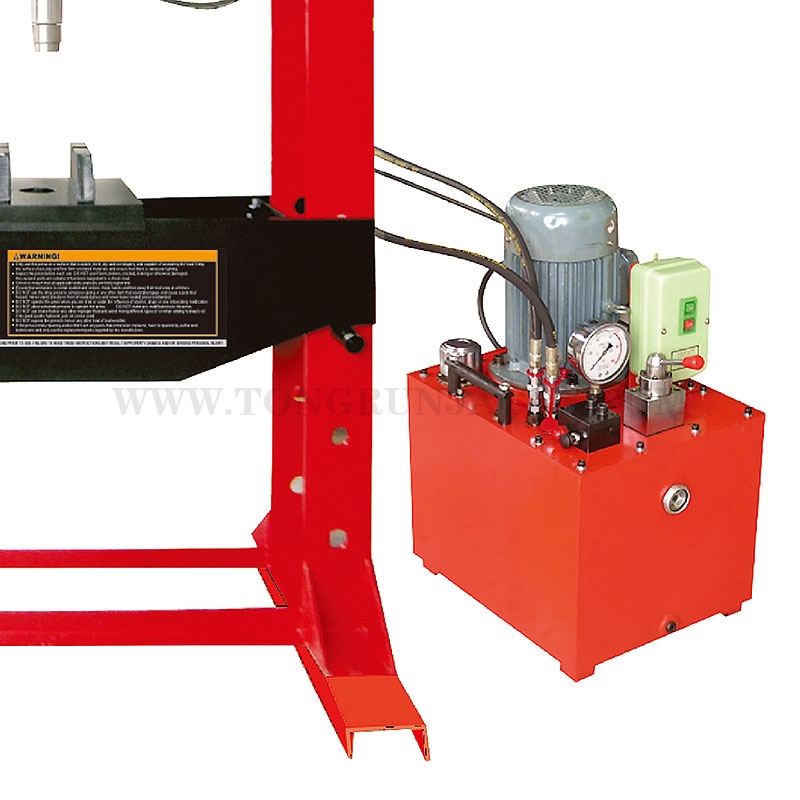

• High quality large diameter hydraulic steel cylinder unit results in lower oil pressure needed to raise the load, helping to reduce wear and extend service life

• Piston-ram is treated and polished to resist skiving

• Piston-ram utilizes a Y-Style polyurethane sealing ring with backup ring, preventing load from falling slowly or bypassing oil drift

• Hydraulics are powered with a high quality oil, which offers better corrosion resistance and high/low temperature flexibility, allowing the unit to operate at temperatures between 40 degrees F and 105 degrees F

• Extra-long handle included for easy pumping force

Common Problems And Solutions

If you use and maintain your equipment properly, it will give you many years of service. Follow the maintenance instructions carefully to keep your equipment in good working condition. Never perform any maintenance on the equipment while it is under a load.

Cleaning

If the moving parts of the equipment are obstructed, use cleaning solvent or another good degreaser to clean the equipment. Remove any existing rust with a penetrating lubricant.

How the Ram Operates

With release valve closed, an upward stroke of the jack handle draws oil from the reservoir tank into the plunger cavity. Hydraulic pressure holds the valve closed, which keeps the oil in the plunger cavity. A downward stroke of the jack handle releases oil into the cylinder, which forces the ram out. This extends the ram. When the ram reaches maximum extension, oil is bypassed back into the reservoir to prevent an over extended ram stroke and possible damage to the vérin. Opening the release valve allows oil to flow back into reservoir. This releases hydraulic pressure on the ram, which results in lowering the ram.

Storing the Ram

1. Fully Retract Ram after use.

2. Place the handle in the upright position.

3. Store in a dry location, recommended indoors.

Note: If the press is stored outdoors, be sure to lubricate all parts before and after use to ensure the press stays in good working condition.

Scan the QR code to read on your phone

Previous

20Ton Hydraulic Shop Press

- TOP