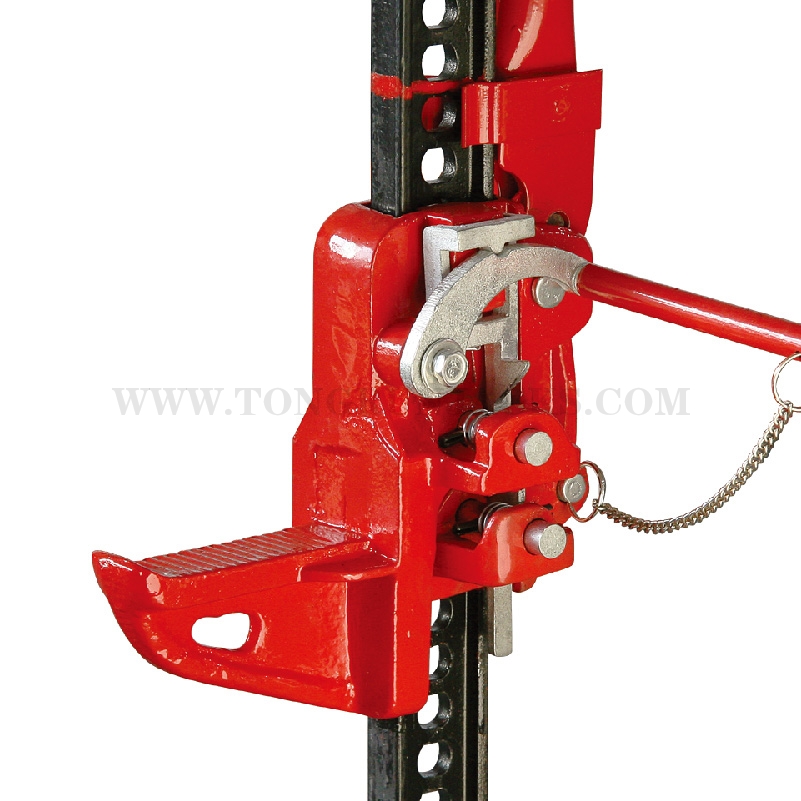

2000 kgs Off-Road Jack

Product Information

This universal Ratcheting Utility Jack is very versatile. It's a perfect choice for any application that deals with lifting, pulling, clamping or spreading. This product is tested for reliability and safety to meet ASME B30.1 Standards

|

Model |

TRA8485(GS) |

Capacity |

2000 kgs |

|

Lifting Range |

130-1060 mm |

Base Size |

260x120x5 mm |

|

Package Size |

1255x250x145 mm |

N.W./G.W. |

13/14 kg |

|

Max. SupportLoad |

130 mm <H<300 mm 300 mm< H<500 mm H > 500 mm |

QTY/20'CY |

580 PCS |

• Features

• Applied Model: T828011CL series

Maintain your equipment. It is recommended that the general condition of any equipment be examined before it is used. Keep your equipment in good repair by adopting a program of conscientious repair and maintenance. Have necessary repairs made by qualified service personnel.

Cleaning

If the moving parts of the equipment are obstructed, use cleaning solvent or another good degreaser to clean the equipment. Remove any existing rust, with a penetrating lubricant.

Do not use motor oil or grease to lubricate the equipment

Rust Prevention:

-Check daily for any signs of rust or corrosion.

Without a load lift the equipment as high as it goes and look under and behind the lifting points. If signs of rust are visible clean as needed.

Storing the Equipment

1. Store in a dry location, recommended indoors.

2. Equipment should be stored in an area where they will not be subjected to damage.

3. If extreme temperatures or chemically active or abrasive environments are involved, the guidance provided in shall be followed.

4. Temperature - When equipment is used at temperatures above 140"F (60"C) or below -20"F (-29"C), the equipment manufacturer or a qualified person should be consulted.

5. Chemically Active Environments -The strength and operation of eqipment can be affected by chemically active environments such as caustic or acid substances or fumes. The equipment manufacturer or a qualified person should be consulted before equipment are used in chemically active environments.

6. Other Environments - The internal workings of equipment can be affected by high moisture, gravel or sand, silt, grit, or other dust-laden air. Equipment subject to these environments should have their inner components frequently cleaned, inspected, and lubricated.

Note: If the equipment is stored outdoors, be sure to lubricate all parts before and after use to ensure the equipment stays in good working condition.

- TOP