2 Ton Heavy Duty Welding Bottle jack

• Welded construction NO LEAK.

• Safety valve prevents the ram from being overextended and causing damage to the cylinder.

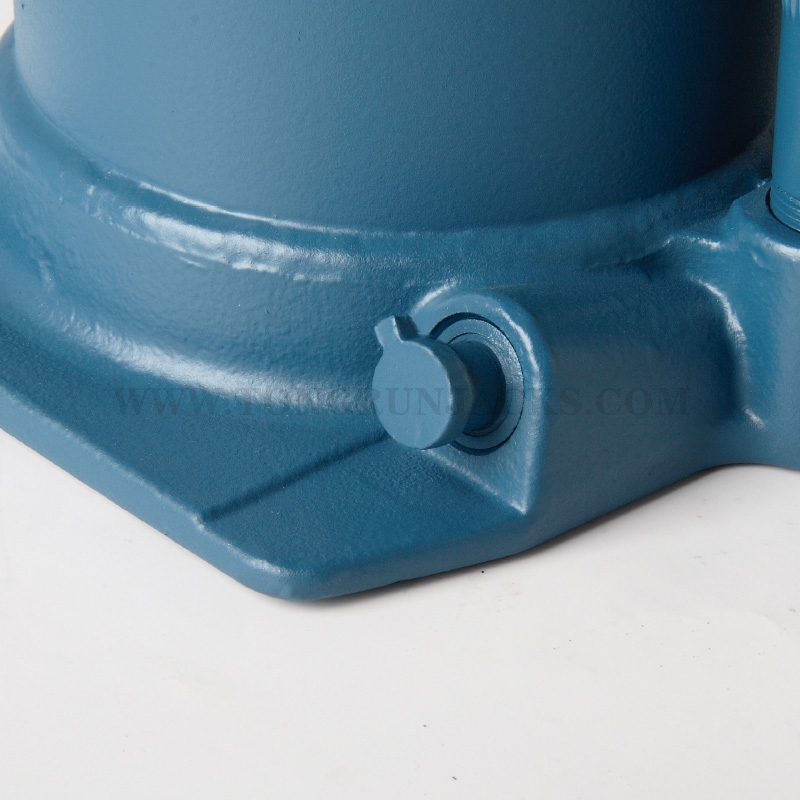

• Inner safety valve prevent the user to adjust the system.

• Arc surface bottom of the steel base to make the load in the center of the piston.

• Prevent rust with ENP (electroless nickel plating) ram piston, make it smooth, bright, and long life.

• Double seals in the pump to prevent the oil leak.

• Light weight forged base provides more steel only where strength is required.

• This design creates a better, stronger design with the tank welded directly to the forged base.

• Longer life than normal screw connection jack due to smooth bearing surfaces and close tolerances.

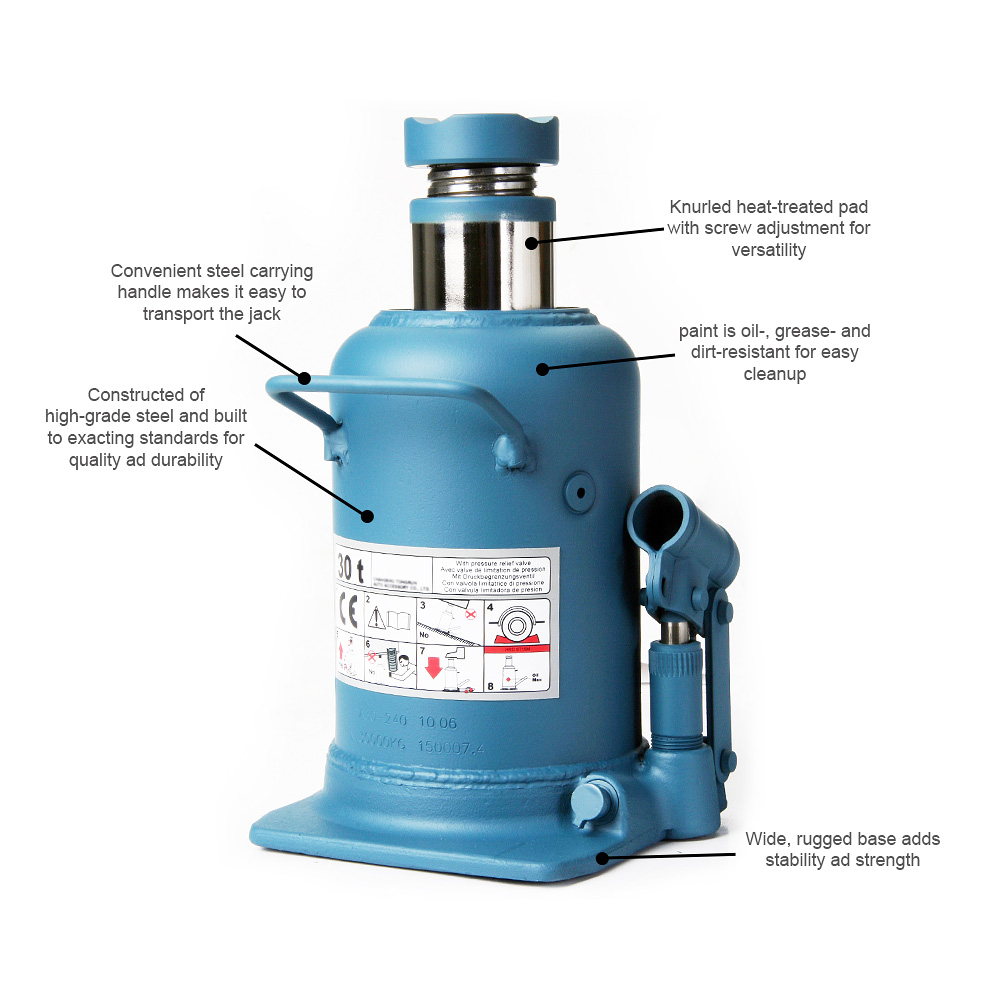

• Carrying handles on big capacity jack for easy transport.

Product Information

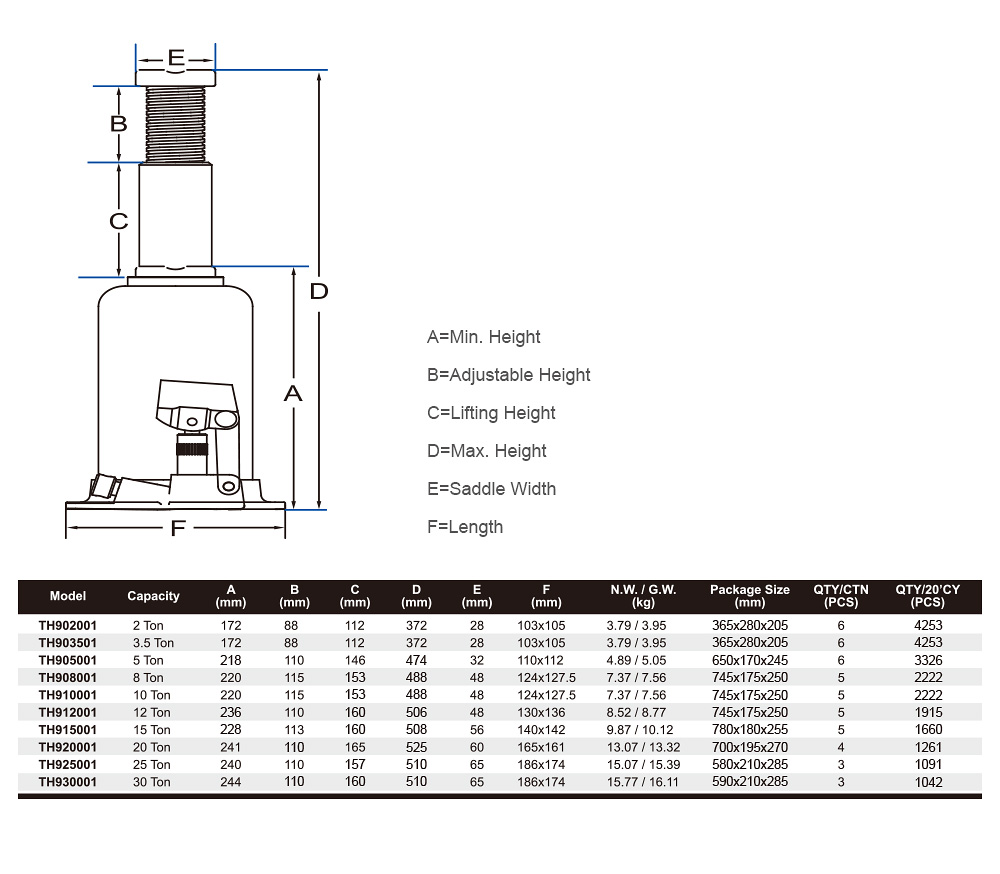

Product Parameters

|

Model |

TH903501 |

Capacity |

3.5 Ton |

|

Min. Height |

172 mm |

Lifting Height |

112 mm |

|

Adjustable Height |

88 mm |

Max. Height |

372 mm |

|

N.W./G.W. |

3.79 / 3.95 kg |

Package Size |

375x290x225 mm |

|

QTY/CTN |

6 PCS |

QTY/20'CY |

4253 PCS |

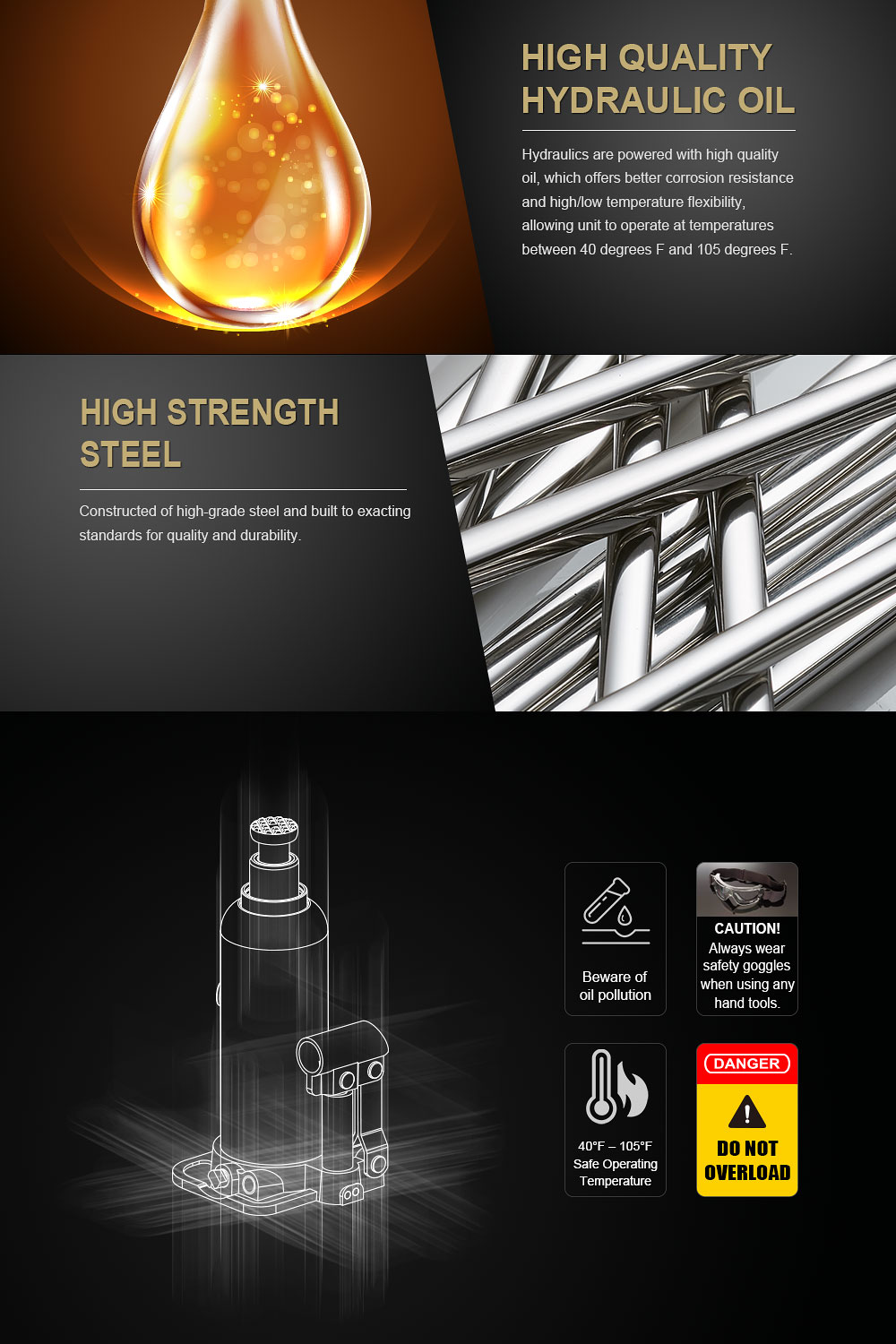

Features

• Zinc plated long handle allows ease of pumping.

• Welded construction NO LEAK.

• Safety valve prevents the ram from being overextended and causing damage to the cylinder.

• Inner safety valve prevent the user to adjust the system.

• Arc surface bottom of the steel base to make the load in the center of the piston.

• Prevent rust with ENP (electroless nickel plating) ram piston, make it smooth, bright, and long life.

• Double seals in the pump to prevent the oil leak.

• Light weight forged base provides more steel only where strength is required.

• This design creates a better, stronger design with the tank welded directly to the forged base.

• Longer life than normal screw connection jack due to smooth bearing surfaces and close tolerances.

• Carrying handles on big capacity jack for easy transport.

Common Problems And Solutions

1. When lifting heavy weights, the mandril fails to rise to the maximum route. When the jack reaches a certain height, and the maximum route is not reached, the mandril cannot rise up any more, which indicates that there is a lack of working oil in the jack, and it should be replenished.

2. The mandril wobbles while rising. Generally the oil return valve is not closed tightly; we can tighten oil return valve needle in counterclockwise direction. If it is still unstable, check whether there is any oil leakage around the pressure rod; if the oil leaks, it indicates that the seal ring of the mandril is damaged, and it should be replaced. If there is no oil leakage, confirm again whether the oil return valve and the inlet valve is already locked, and also check sealing gasket conditions in the cylinder end joint of pressure rod; if all the above is normal, then it indicates that the seal ring is damaged, or the fixed screw is loosening, we should replace it or tighten the screw.

3. The mandril fails to rise while no-load. First check the oil amount of the jack, and we should add oil when insufficient. If jack is not short of oil, we can loosen the oil return valve needle of the jack, remove the oil plug of oil filling port, then trample on the jack base by our feet, repeatedly pull up the mandril and press down again by our hands for several times, in order to exhaust air; after the above actions are completed, tighten the oil plug of oil filling port and oil return valve tightly, and then try again the no-load mandril; if the mandril still cannot rise, lay jack flat, remove the oil return valve, check whether the valve and seat contact well; if there is dirt, it should be removed; if there is pit, slot and uneven, it should be replaced. Finally check whether the oil inlet valve is well sealed and the sealing ring of mandril is damaged or falls off. If any, replace it in time.

4. Oil leakage, can be seen by visual observation. The oil leakage area of the jack is usually in the base and the cylinder joint, around the mandril, in the lock thread of the oil return valve, in the fixed oil plug of the oil filling port, around pressure rod etc. The cause of oil leakage is usually the damage of sealing gasket, it must be replaced in time.

- TOP