- Inquiry

3 Ton Ultra Thin Full-rise Scissor Lift QJYJ30-CB

• Mechanical safety lock engaged automatically when lowering • Four cylinders design with anti-surge valves • Low voltage control unit • Rubber pads160x125x35mm 4pcs • Drive-on ramps lock into positionas platform extending • Easy access grease nipple design • Infrared synchronization protection system • Drive-by-wire control • Hight limit switch • Secondary descending alarm& stop

PRODUCT PARAMETERS

| Model | QJYJ30-CB |

| Capacity | 3.0 Ton |

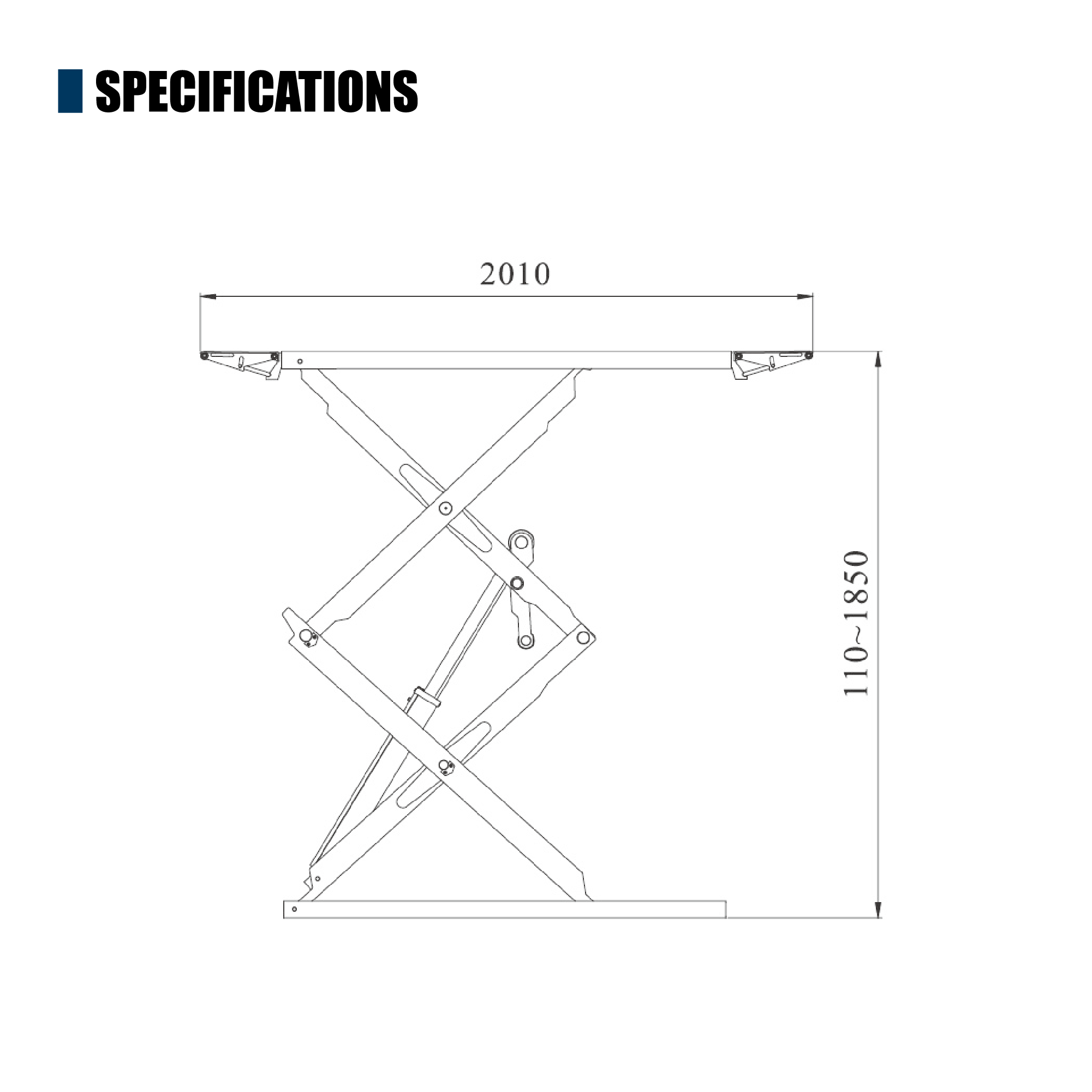

| Lifting height | 1850mm |

| Min height | 110mm |

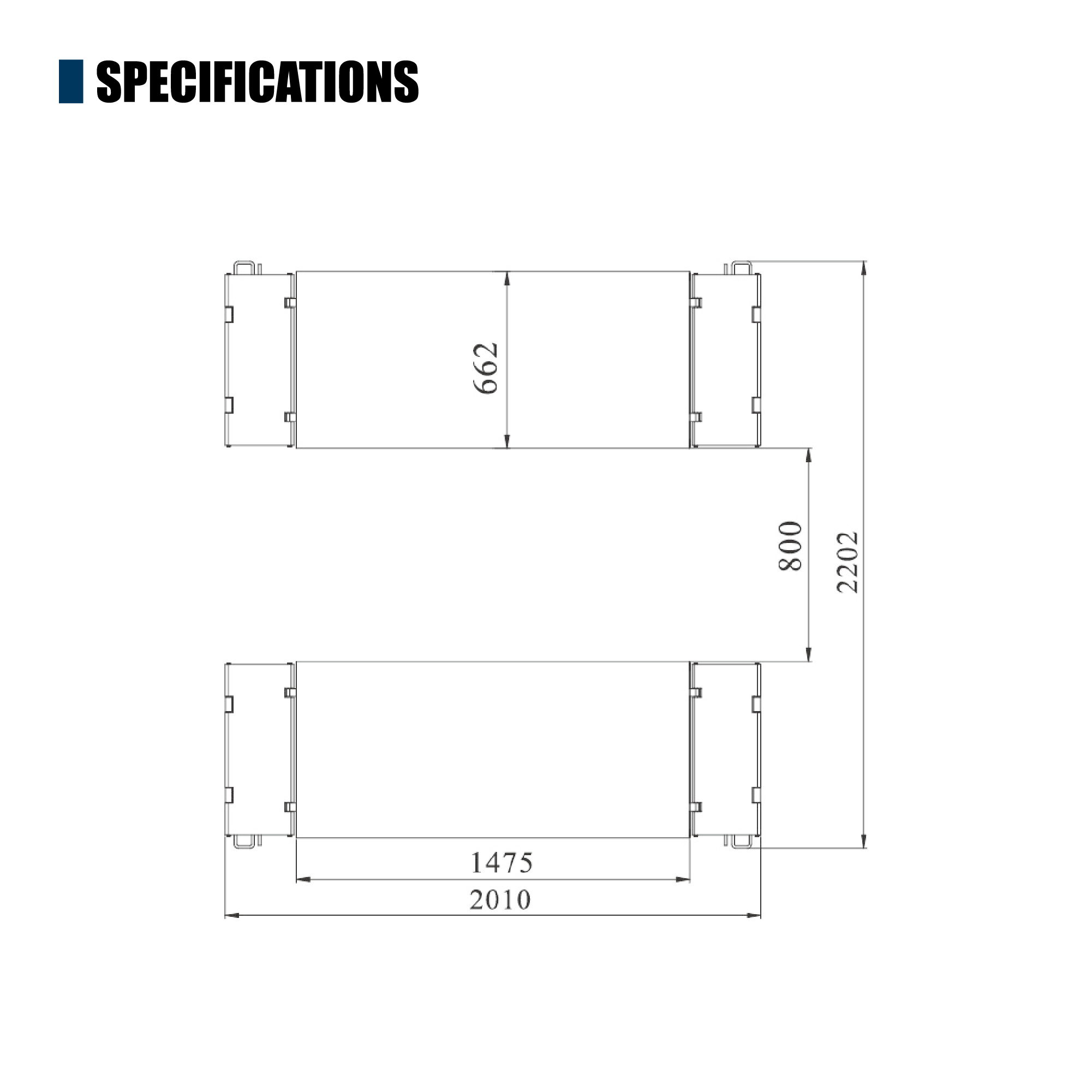

| Platform L*W | 1475~2010x662mm |

| Power supply | 220V IPH 50/60Hz 2.2KW 220/380V 3PH 50/60Hz 2.2KW |

About the Product

Product Information

This Scissor Lift offers the convenience of wide or narrow installation wrapped up into one configurable package. The durable, safe and reliable to suit virtually every vehicle-lifting requirement. It's a simple yet highly sophisticated lift designed to minimize service and maintenance costs while delivering low operating expenses and high productivity.

Product Parameters

| Model | Capacity |

Lifting height (mm) |

Min height (mm) |

Platform L*W (mm) |

Power supply |

| QJYJ30-CB | 3 Ton | 1850 | 110 | 1475~2010x662mm | 220V IPH 50/60Hz 2.2KW 220/380V 3PH 50/60Hz 2.2KW |

Matters need attention

Common Problems And Solutions

Sequence of Lockout Procedure:

1:Notify all affected employees that a lockout is being performed for servicing or maintenance and that the lift must be shut down and locked out to perform the servicing or maintenance.

2:Unload the subject lift (remove vehicle). Shut it down and assure the disconnect switch is "OFF" if one is provided on the lift.

3:The authorized lockout person operates the main energy isolation device removing power to the lift being taken out of service. Stored or residual energy (such as capacitors, springs, elevated machine members, hydraulic systems, air, or etc.) must be dissipated or restrained by methods such as grounding, repositioning, blocking, bleeding down, etc. If this is a lockable device, the authorized lockout person places the assigned padlock on the device to prevent its unintentional reactivation. An appropriate tag is applied stating the person's name, at least 3" x 6" in size, an easily noticeably color, and states not to operate device or remove tag. If this device is a non-lockable circuit breaker or fuse, replace circuit with a "dummy" device and tag it appropriately as mentioned above.

4:Ensure that the equipment is disconnected from the energy sources' by first checking that no personnel are exposed, then verify the isolation of the equipment by operating the push button or other normal operating controls' or by testing to make certain the equipment will not operate. . Be sure to return any switches to the "OFF" position.

5:The equipment is now locked out and ready for the required maintenance or service.

Restoring Equipment to Service:

1:Check the lift and the immediate area around the lift to ensure that nonessential items have been removed (clear all tools, vehicles and personnel) and that the completion of all lift components are operationally intact.

2:The authorized person can now remove the lock (or dummy circuit breaker or fuse) and tag. Activate the energy isolating device so that the lift may again be placed into operation.

Ingredients-

Premium hydraulic oil. P.reventing from oil leakage

Hydraulics are powered with high quality oil,which offers better corrosion resistance and high/low temperature flexibility,allowing unit to operate at temperatures between 40 degrees F and 105 degrees F.

Automatic welded

This valve is welded in fine steel, having the features of handy to operate, good seal, reliable performance and having the function of automatic air-locking dropping material.

High Stregth Steel

Constructed of high-grade steel and built to exacting standards for quality and durability.

You May Also Like

Model

Features

• Mechanical safety lockengaged automaticallywhen lowering • Low voltage control unit • Platform extending for long vehicles • Hight limit switch • Easy access grease nipple design • Secondary descending alarm& stop • Rubber pads115x100x70mm 4pcs • Infrared synchronization protection system • Drive-by-wire control

• Full automatic penumatic tilting column. Independent right helper arm, with pneumatic tire lifting device 360 rotary tire pressing helper arm. Four angle directional adjustable tire pressing shovel.

• The wheels construction for more stability and esy rolling. • Adjustable mounting arms, accommodate a majority of engine blocks, both foreign and domestic. • Mounting plate rotates 360 degree and can be locked in 8 different positions. • Heavy gauge tubular steel construction. • Roll-around engine stand assembles easily.

• The wheels construction for more stability and esy rolling. • Adjustable mounting arms, accommodate a majority of engine blocks, both foreign and domestic. • Mounting plate rotates 360 degree and can be locked in 8 different positions. • Heavy gauge tubular steel construction. • Roll-around engine stand assembles easily.

• The wheels construction for more stability and esy rolling. • Adjustable mounting arms, accommodate a majority of engine blocks, both foreign and domestic. • Mounting plate rotates 360 degree and can be locked in 8 different positions. • Heavy gauge tubular steel construction. • Roll-around engine stand assembles easily.

• The wheels construction for more stability and esy rolling. • Adjustable mounting arms, accommodate a majority of engine blocks, both foreign and domestic. • Mounting plate rotates 360 degree and can be locked in 8 different positions. • Heavy gauge tubular steel construction. • Roll-around engine stand assembles easily.