- Inquiry

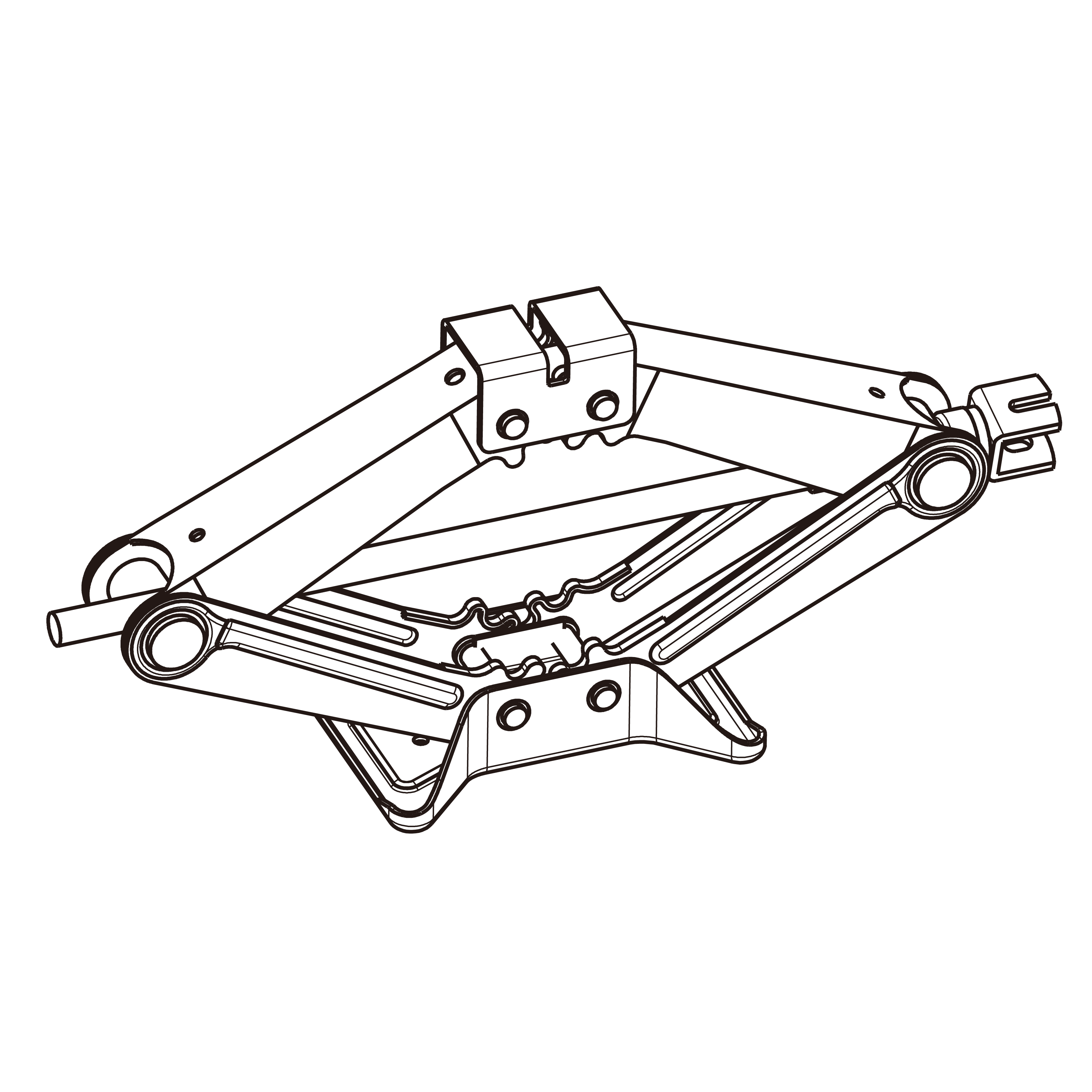

1 Ton Scissor Jack T10152-GS

• Quickly & easily change your tire. • Compact design • Collapsible and easy to store in your car or garage. • Wide base and saddle provides stability under load. • Constructed of heavy duty steel • Use for most cars for tire removing.

PRODUCT PARAMETERS

| Model | T10152-GS |

| Capacity | 1.5 Ton |

| Min.Height | 95mm |

| Max.Height | 395mm |

| Total Length | 450mm |

| Stroke With Rated load | 230-390mm |

| N.W./G.W. | 3.5/3.6kg |

| Package Size | 660x470x230mm |

| QTY/CTN | 10pcs |

| QTY/20'CY | 4800pcs |

About the Product

Product Information

This collapsible, compact steel scissor jack can be used as a rugged replacement jack or an extra utility jack that can be stored in the trunk of your car. The extra-wide base offers easy positioning, and the one-piece handle delivers on-the-spot quick response and speed when you need it.

Product Parameters

| Model | Capacity | Min.Height(mm) | Max.Height(mm) | Total Length(mm) | Stroke With Rated load (mm) | N.W./G.W.(kg) | Package Size(mm) | QTY/CTN(pcs) | QTY/20'CY(pcs) |

| T10104 | 1 Ton | 80 | 330 | 365 | 124 | 1.5/1.65 | 475x395x200 | 10 | 6000 |

| T10151 | 1.5 Ton | 100 | 370 | 415 | 135 | 2.15/2.3 | 505x405x240 | 10 | 5000 |

| T10101-GS | 1 Ton | 88 | 380 | 426 | 200-370 | 2.5/2.8 | 500x455x255 | 10 | 4950 |

| T10152-GS | 1.5 Ton | 95 | 390 | 450 | 230-390 | 3.3/3.5 | 660x470x230 | 10 | 3600 |

| T10202-GS | 2 Ton | 120 | 395 | 450 | 260-390 | 3.5/4 | 660x470x260x | 10 | 4800 |

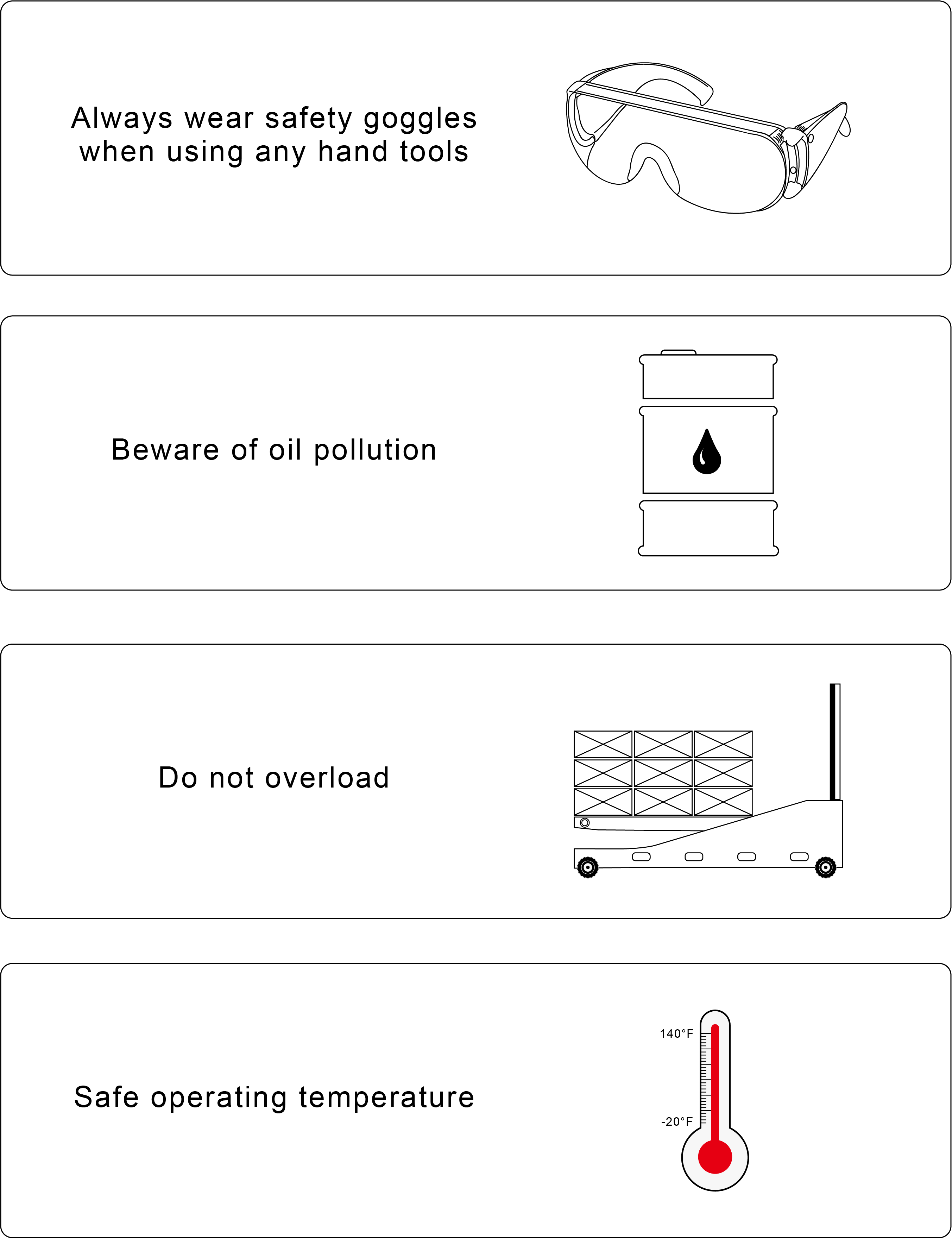

Matters need attention

Common Problems And Solutions

Maintain your equipment. It is recommended that the general condition of any equipment be examined before it is used. Keep your equipment in good repair by adopting a program of conscientious repair and maintenance. Have necessary repairs made by qualified service personnel.

Cleaning:

If the moving parts of the equipment are obstructed, use cleaning solvent or another good degreaser to clean the equipment. Remove any existing rust, with a penetrating lubricant.

Do not use motor oil or grease to lubricate the equipment.

Rust Prevention:

Check daily for any signs of rust or corrosion.

Without a load lift the equipment as high as it goes and look under and behind the lifting points. If signs of rust are visible clean as needed.

Storing the Equipment:

1. Store in a dry location, recommended indoors.

2. Equipment should be stored in an area where they will not be subjected to damage.

3. If extreme temperatures or chemically active or abrasive environments are involved, the guidance provided in shall be followed.

4. Temperature - When equipment is used at temperatures above 140"F (60"C) or below -20"F (-29"C), the equipment manufacturer or a qualified person should be consulted.

5. Chemically Active Environments -The strength and operation of eqipment can be affected by chemically active environments such as caustic or acid substances or fumes. The equipment manufacturer or a qualified person should be consulted before equipment are used in chemically active environments.

6. Other Environments - The internal workings of equipment can be affected by high moisture, gravel or sand, silt, grit, or other dust-laden air. Equipment subject to these environments should have their inner components frequently cleaned, inspected, and lubricated.

Note: If the equipment is stored outdoors, be sure to lubricate all parts before and after use to ensure the equipment stays in good working condition.This procedure should ONLY be performed by a qualified technician.

a.Using an oil gun, pour oil slowly into the pump housing to overflowing.

b.Reassemble, and wipe excess oil from the tool.

Ingredients-

Premium hydraulic oil. P.reventing from oil leakage

Hydraulics are powered with high quality oil,which offers better corrosion resistance and high/low temperature flexibility,allowing unit to operate at temperatures between 40 degrees F and 105 degrees F.

Automatic welded

This valve is welded in fine steel, having the features of handy to operate, good seal, reliable performance and having the function of automatic air-locking dropping material.

High Stregth Steel

Constructed of high-grade steel and built to exacting standards for quality and durability.

You May Also Like

Model

Features

• Mechanical safety lockengaged automaticallywhen lowering • Low voltage control unit • Platform extending for long vehicles • Hight limit switch • Easy access grease nipple design • Secondary descending alarm& stop • Rubber pads115x100x70mm 4pcs • Infrared synchronization protection system • Drive-by-wire control

• Full automatic penumatic tilting column. Independent right helper arm, with pneumatic tire lifting device 360 rotary tire pressing helper arm. Four angle directional adjustable tire pressing shovel.

• Bucket lock for securing contents • Soft-closing drawer slides for preventing wear and tear • Ideal storage for your workshop or garage • 4 wheels (2 swivel, 2 fixed) for easy movement • Easy assembly

• The wheels construction for more stability and esy rolling. • Adjustable mounting arms, accommodate a majority of engine blocks, both foreign and domestic. • Mounting plate rotates 360 degree and can be locked in 8 different positions. • Heavy gauge tubular steel construction. • Roll-around engine stand assembles easily.

• Heavy-duty zinc plated steel construction • Drop-forged steel safety hooks with latches • Aircraft quality cable • High tensile swivel and yoke add additional strength and security

• ATV Loading Ramp provides you with a way to easily load and unload your ATV and power equipment in and out of the back of a pickup truck. These ramps make transporting your ATV a simple task and a non-skid surface ensures safety in all conditions.